Features of Latest Technology Durable Complete Feed Mill

1. Advanced technology With reasonable technology, easy operation and low energy consumption. It can produce 5000-15000 tons mash and pellet feed per shift annually;

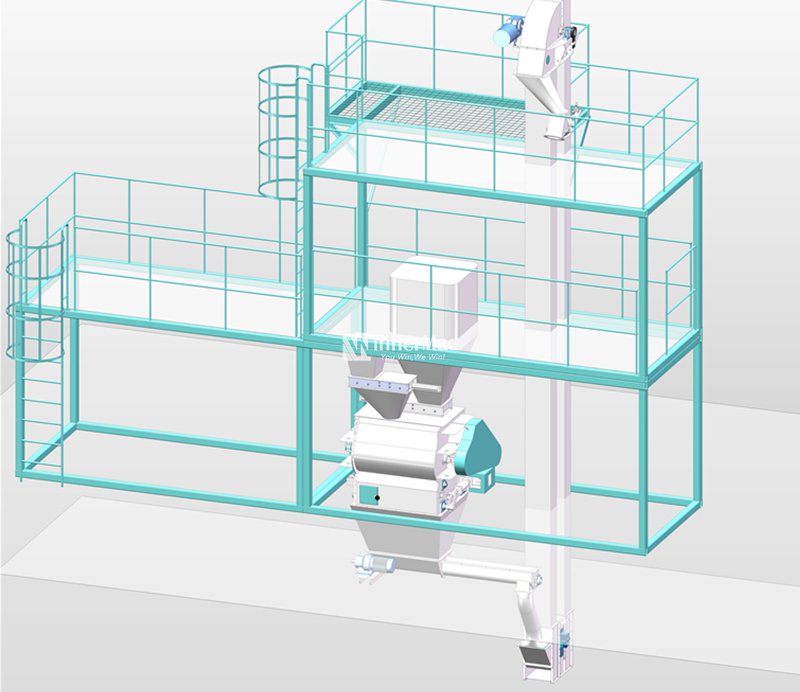

2. Modular Structure The plant is compact, occupies less floor space and has low requirement on the mill tower, and needs low investment in civil works. The containerized modular structure is convenient for assembly and disassemble, facilitates the shipment and installation;

3. Automatic and Centralized control The analogue panel is adopted. All machines can be interlocked and safety alarm deviceis available. The operation is simple and convenient;

4. Wide applicable scope The plant can produce both poultry&livestock&fish feed. It is suitable for medium and small sized feed mills and breeding farms.

0.8-1t/h animal feed pellet plant adopt manual batching system with single grinding line, single mixing line, single pelleting line and manual packing line. this small feed pellet plant

is designed as container modular type which is easy to dismounting, transportation and assembly. The total power is about 90Kw, dimension is : 6x4x8m, matching 0.5T boiler. 0.8-1t/h feed pellet plant is characterized by compact design and reasonable structure, and the satisfaction of environment protection requirements, meanwhile it can be directed to customers design.

|

Model

|

Total Power

(kw)

|

Output

(t/h)

|

Floor Area(m)

(L*W*H)

|

Main Machines

model

|

|

SKJZ1800

|

55

|

0.5-1.5

|

6*4*8

|

SFSP50.SLHY0.4,

SZLH25(15kw).SNSZ80

|

1.cleaner: precleaner SCYW50, output 1-3t/h

2.grinding machine: hammer mill SFSP568-Ⅰwith power 22KW, output: 2-3t/h

3.mixing equipment: mixer SHSJ0.5 with 7.5kw, 250kg/P, output:2-3.5t/h, homogeneity CV≤5%.

4.pelletize equipment: pellet mill SZLH25 with 22kw, output:0.8-1t/h. Cooling machine: SNSZ1.2,output 1-1.5T/H.

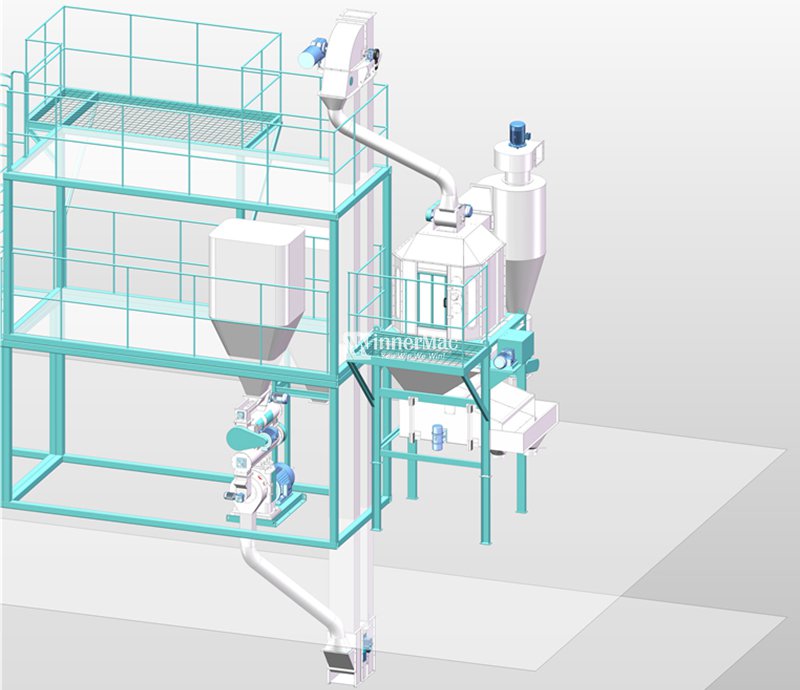

Technological process chart:

RM receiving and cleaning process---grinding process---manual batching and mixing process--pelleting process- Auxiliary system.

RM receiving and cleaning process: Cleaning is playing a role to remove the impurities from raw material, including large impurities such as nonmagnetic impurity like rope, clod and corn cob, and magnetic impurity like iron nails. It will ensure the quality of products and safety of following processing machine.

cleaner: precleaner SCYW50, output 1-3t/h

Grinding process:

grinding is playing a role to enlarge the surface area of feed which is good for digestion and absorption of animal, improve the material processability. Single hammer mill is used in this grinding process of SKJZ1800 feed set, a 1m3 pre-grinding bin is set above the hammer mill. To make sure the safe running of hammer mill, the raw material should be removed impurities through magnetic device. The cleaned material will go to the grinding bin for grinding. After grinding, the material will transported into bucket elevator by screw conveyor then go into the batching bins. when transported by screw conveyor, auxiliary suction system is also adopted to save energy consumption, prevent dust and reduce the material's temperature and improve the grinding efficiency.

grinding machine: hammer mill SFSP568-Ⅰwith power 22KW, output: 2-3t/h

Mixing process:

mixing is the process for kinds raw material for feed interblend each other to be in homogeneous distribution under the external force after batching . In this feed set, a 1m³pre-mixing bin is set above the mixer and with an extra manual adding hopper. The material will be unload by conveyor after mixing.

mixing equipment: mixer SHSJ0.5 with 7.5kw, 250kg/P, output:2-3.5t/h, homogeneity CV≤5%.

Pelleting process: the purpose of pelletize is to make use of the heat, moisture, and pressure in pelleting process to pelletize the feed which may be loose, easy to dust, with poor palatability and hard to transport, then the feed could be with better palatability, lower feed conversion rate, reduce feed waste and environmental pollution. In this process, we use single pellet mill, with a 2m3 pre-pellet bin above pellet mill. The feed will go into cooling sifter to be cooled and screened through bucket elevator, and go to manual bagging part finally after pellet.

pelletize equipment: pellet mill SZLH25 with 22kw, output:0.8-1t/h. Cooling machine: SNSZ1.2,output 1-1.5T/H.

Auxiliary system: 0.8-1t/h SKJZ1800 feed set adopt dust collection system in material receiving process to improve the working condition, oil adding system is usually added in mixing system to improve feed palatability.

After-sale service

Warranty: 1 years

Our professional service includes: Free training, Guidance Installation and Debugging.

Livestock animal

Livestock animal